Researchers at the University of Aberdeen are developing innovative 3D-printed metal connectors for lightweight steel housing systems that make buildings easier to reuse, adapt, and recycle.

These smart, high-precision components make structures faster to assemble and easier to take apart, allowing buildings to be adapted, reused, or fully recycled rather than demolished.

By integrating cutting-edge metal 3D-printing technologies into construction, the project aims to help the steel construction industry build more efficiently, reduce waste, and move toward a circular and sustainable future.

Dr Alireza Bagheri, a senior lecturer in Engineering, said: “The aim of our research is to build homes and structures in a smarter, more sustainable way.

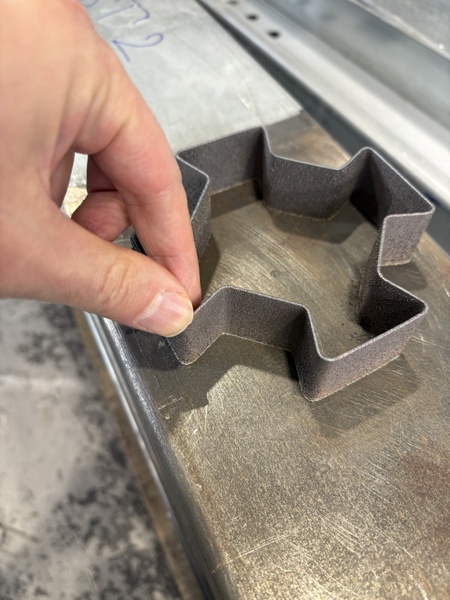

“The 3D-printed steel connectors we have developed enable buildings to be assembled, adapted, and reused with ease, overcoming the limitations of traditional mechanical connections and showing that low-waste, circular construction is achievable with today’s technology. This research provides a practical alternative.

“By designing connectors that allow lightweight steel buildings to be quickly assembled and fully disassembled without damaging components, the work supports faster, more efficient construction, reduces material waste, increases adaptability and building lifespan, and lowers overall environmental impact.”

The researchers say the project offers a scalable route toward a future in which buildings are treated as long-term resources rather than disposable products.

Dr Bagheri added: “This approach is entirely new. No existing construction system currently combines metal 3D-printed connectors with cold-formed lightweight steel to enable rapid, automated assembly and complete disassembly for reuse.

“A major technical innovation has been developing a method to print directly onto very thin steel substrates, typically 1-3 mm thick, which significantly reduces distortion or residual stress. This breakthrough has been central to making the technology structurally feasible and suitable for real-world construction.”

The project is a collaboration between the University of Aberdeen and Politecnico di Milano, bringing together expertise in structural and architectural engineering, advanced manufacturing, and cold-formed steel systems.

The concept originated in 2023 and was subsequently developed through the work of PhD student Ehsan Bakhshivand, funded by the School of Engineering in collaboration with Professor Ornella Iuorio, with additional support from Professor Barbara Previtali and her team at Politecnico di Milano. It was realised through extensive prototyping and 3D printing at AS_Lab and AddMe Lab in Politecnico di Milano, finite element modelling, and full-scale structural testing, further advanced by contributions from postdoctoral researcher Dr Chuandong Xie, supported by EPSRC grant (EP/W026376/1).