The Microscopy and Histology Core Facility has a wealth of knowledge and expertise to assist you with your research. We are available to work with researchers within the University of Aberdeen and also with external laboratories and commercial companies.

Services

- Direct instrument use - we offer access to our equipment following training with facility staff.

- Training - we can organise training on our equipment one to one or in small groups. We also run regular microscopy courses covering all the important information regarding the systems we have within our facility.

- Consultancy and advice services - we can be contracted for consulting services to provide interpretation and analysis of data.

- Research projects - we are able to carry out research for you. We can prepare samples, take images and produce data as required.

Contact us at microscopy@abdn.ac.uk for more information and a quote for any of the above services.

Equipment

- Optical Microscopy and Light Sheet Microscopy

-

Now available in the IMS - ZEISS Lightsheet 7

A team led by Debbie Wilkinson were awarded a BBSRC ALERT22 grant to buy a light sheet microscope, a type of microscope not currently available in NE Scotland. The Zeiss Lightsheet 7 system is now available for booking!

This system allows imaging of cleared samples up to 2cm, (e.g. entire embryos, organoid cultures and adult rodent organs) and will have full environmental control to image live samples, plus 2 cameras for fast simultaneous imaging of 2 colours and 4 laser lines (405nm, 488nm, 561nm and 638nm).

If you are interested in using this new system or hearing more about what it can do for you, please contact Debbie debbie.wilkinson@abdn.ac.uk

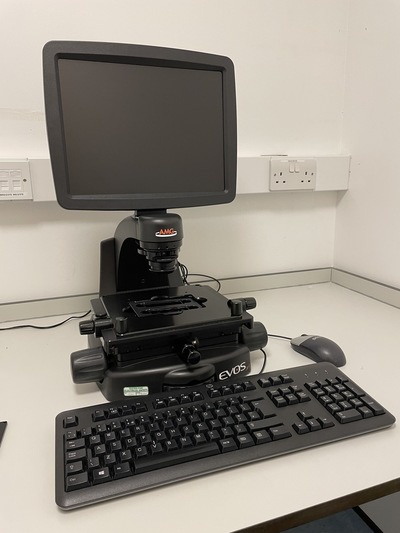

EVOS XL light microscope

- An all in one microscope with phase and colour brightfield imaging capabilities

- Samples can be viewed on slides or tissue culture plates

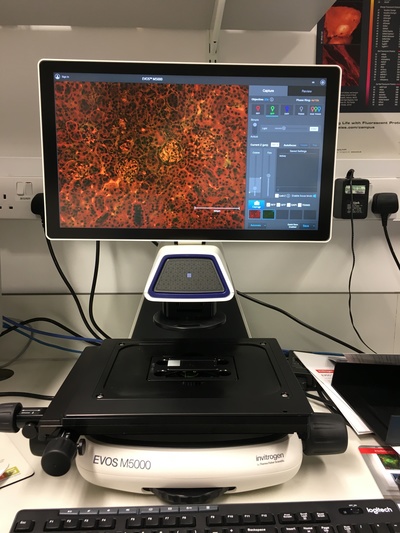

EVOS M5000 fluorescence microscope

- 3 colour fluorescence, transmitted light and colour imaging

- Autofocus, z stack and time lapse imaging and single click multi channel capture

- Software for fast acquisition and analysis

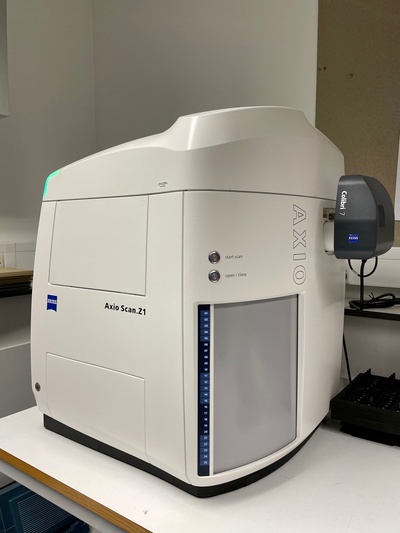

ZEISS AxioScan Z1 slide scanner

- An entire sample on a slide can be imaged, both brightfield and 4 colour fluorescence

- Up to 100 slides can be scanned in one batch

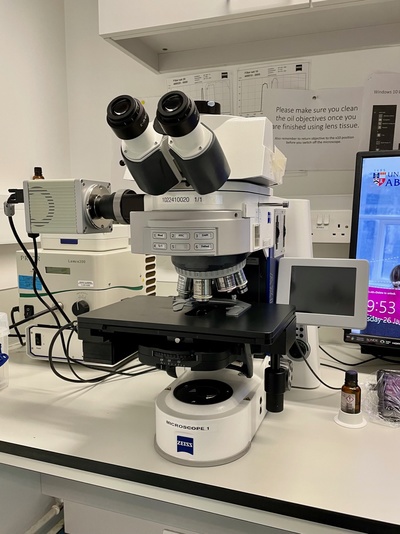

ZEISS Imager M2 upright microscope (Nessie)

- A fully motorised filter turret and z focus

- Hamamatsu Flash 4 LT camera

- Fluorescence and phase contrast imaging

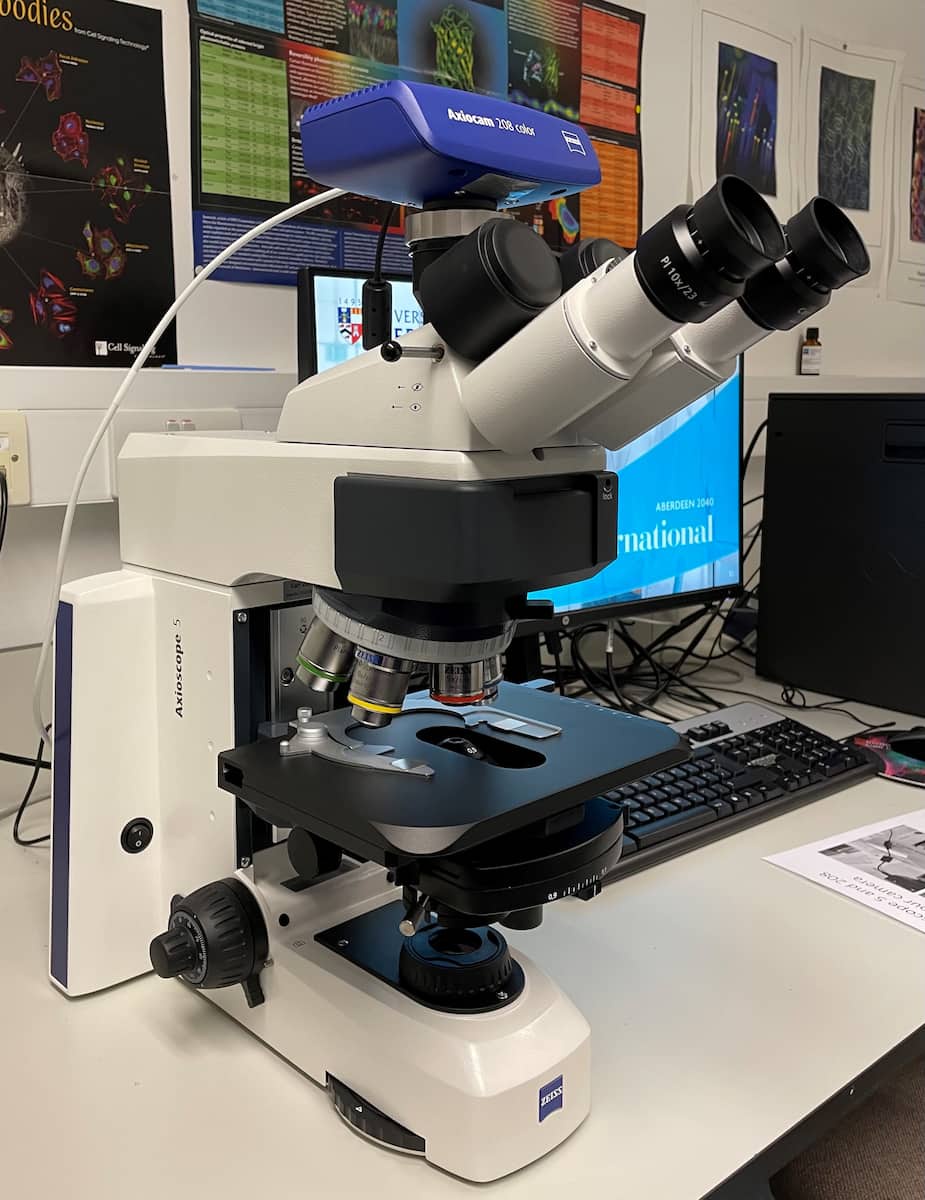

ZEISS Axioscope 5 upright microscope (Kelpie)

- Brightfield imaging

- Zeiss 712 colour camera

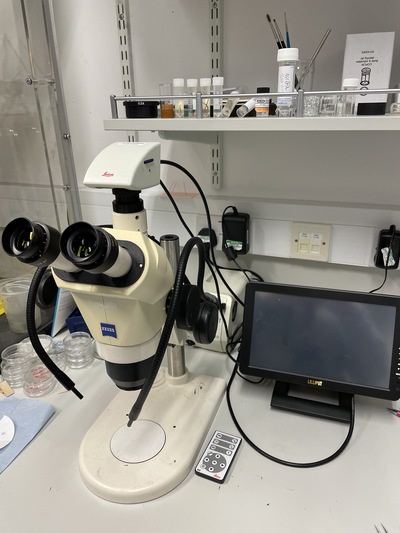

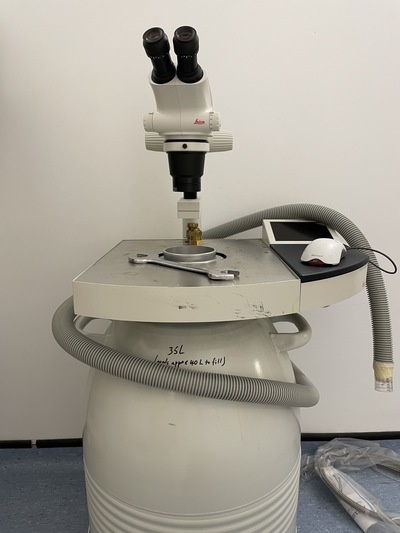

ZEISS stereo zoom microscope

- Dissecting microscope with Leica MC170 HD camera

HoloMonitor

- Incubator tolerant phase imaging microscope

- Label free cell culture analysis

ZEISS Axio Observer Z1 invert microscope (Haggis)

- Incubator for live cell work

- DIC and fluorescence imaging

- Motorised filters and Flash 4 camera

- Oil objectives for higher resolution imaging

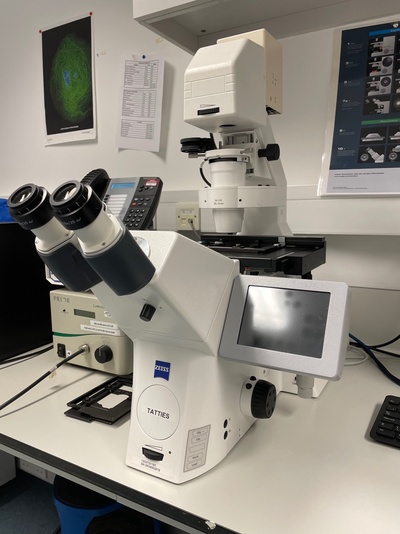

ZEISS Axio Observer Z1 invert microscope (Tatties)

- Fluorescence and phase contrast imaging

- Motorised filters and Zeiss 503 camera

- Long distance x20 and x40 objectives

- Confocal Microscopy

-

ZEISS LSM880 confocal microscope + Airyscan Fast

- Incubator for live cell work and motorised stage

- Airyscan Fast gives an instant 4-8x improvement of signal to noise compared to normal confocal

- Enhanced resolution in x, y and z with high acquisition speed

ZEISS LSM710 confocal microscope

- Inverted confocal microscope

- Motorised stage and a wide range of laser lines

Ultraview VoX spinning disk confocal microscope

- Acquisition of images at a very high frame rate

- Minimum illumination of samples for gentle imaging

- Faster than point scanning confocal so good for live cell imaging

- Electron Microscopy

-

Leica UC6 and UC7T ultramicrotomes

- Ultrathin sectioning for TEM

- Sectioning onto grids, coverslips and wafers

- Cryoultramicrotomy available

Ted Pella Biowave microwave tissue processor

- Rapid sample processing

- Microwave and vacuum function to enhance sample preparation

Leica Empact 2/RTS high pressure freezer

- Cryo-fixation of samples for TEM

- Enhanced preservation of sample morphology

Leica AFS2/FSP automated freeze substitution system

- Low temperature processing of TEM samples

- Preservation of epitopes for immuno TEM preparation

Bal-Tec Critical Point Dryer- For drying SEM samples

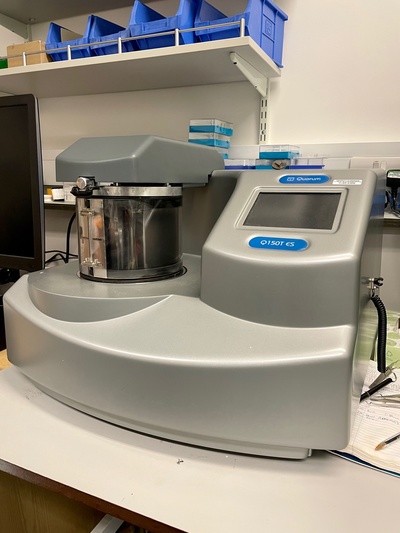

Quorum Q150T ES Sputter Coater

- Capable of sputtering and carbon coating

JEOL 1400 plus TEM

- AMT UltraVUE camera

- Advanced, user friendly TEM to allow visualisation of samples at high magnification

- Tomography allowing 3D visualisation of samples

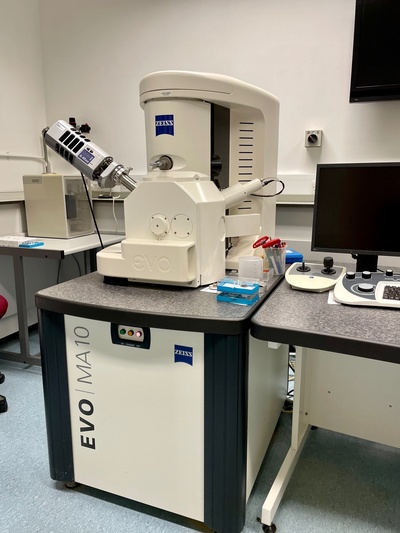

ZEISS EVO MA10 SEM

- Oxford INCA x-ray microanalysis

- An easy to use SEM with a magnification range of x20 - x50,000

- Resolution is ~5nm in biological samples

Field Emission SEM available in the Meston Building, more info can be found on the ACEMAC website .

- Histology

-

Leica RM2165 and RM2125RT microtomes

- Sectioning of histological samples embedded in paraffin or resin

- Multiple blade holders allowing sectioning of wide range of sample types

Ted Pella Biowave microwave tissue processor

- Microwave and vacuum function for sample processing, staining, IHC

Leica 1850 UV and 1850 cryostats

- Sectioning of samples that have been snap frozen

- Disposable and Tungsten Carbide blade holders for variety of sample types

Thermo Shandon Citadel and Leica EMTP tissue processors

- Automated processing of samples

- Process to acrylic, lowicryl and epoxy resins

Leica embedding centre

- With heated forceps for paraffin embedding

Deparaffinization and Staining station

- Deparaffinization, dehydration for pre-staining

- Multiple histological stains available (H&E set up)

- Rehydration, clearing and coverslipping

- Micro CT

-

Skyscan 1072

- Sample size up to 1.5cm x 3cm

- Resolution of up to 4µm

- Magnification between x15 and x120

Nikon XT H 225ST

- Can be used to scan a wide variety of samples

- Resolution 5 - 125µm voxel size

- Maximum sample diameter of 25cm (weight 30kg)