Most of the dangerous phenomena related to drilling are normally explained terms of the dynamics of the BHA and its interactions with its surroundings. Although the BHA is undoubtedly important, and in great extent responsible for the overall dynamics of the system, it seems that the drill-pipes have been increasingly neglected by the models for drill-strings.

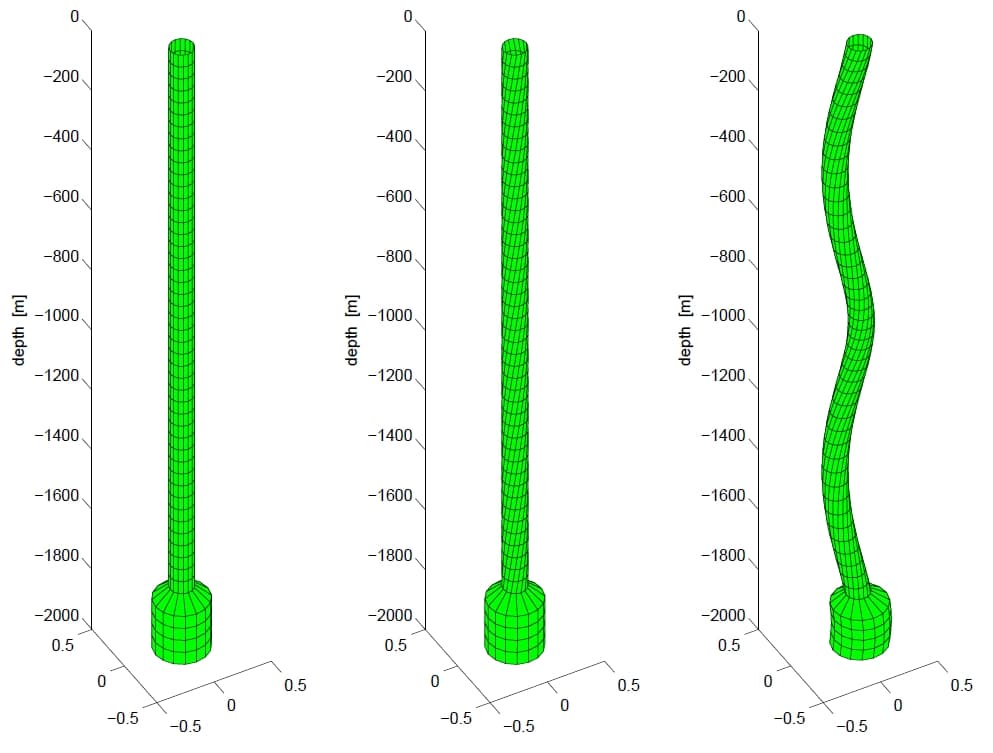

The drill-pipes section constitutes roughly 90 % of the total length of the drill-string, 80 % of its mass, with borehole to drill-pipe ratio around 3 has larger clearance than the BHA, and is overall a long and slender structure. Its dynamics and geometrical behaviour should be better analysed for a greater understanding of underlying phenomena. Specifically, the behaviour of the drill-pipes while operating under torsional vibrations is thought to be of great importance. For example, under stick-slip oscillations the torque on the drill-string increases and may result in torsional buckling of the drill-pipes, incurring in a helical configuration. In passing from a straight to a helical shape, the apparent length of the drill-string will reduce, affecting the contact forces at the bit-rock interface.

This project focuses on developing and analysing a number of mathematical models in order to investigate the dynamics of the drill-string, with added attention to the drill-pipes section. Lower dimensional models are initially used to investigate the torsional dynamics of the drill-string, describing in particular the stick-slip limit-cycle and its limits of existence. Then a mathematical formulation, originally developed for MEMS devices by Liu et al. (2007), is used as a base for an integrated model for drill-strings using the Cosserat theory of rods. Boundary conditions relevant for drilling operation are introduced, such as velocity of top-drive, frictional torque on drill-bit-rock interface and contact with borehole wall, and a numerical simulation procedure is established. Simulations are performed under stick-slip occurrence, and the behaviour of the drill-pipes along the drill-string is analysed. Special attention is given to the helical configurations taken by the drill-string under torsional, axial and lateral loads, seen in the simulations and experimentally. The growth of the helix before and after contact with the borehole wall, and the end shortening of the drill-string during such growth are studied in details.