Predicting gas turbine emissions through deep learning and data modelling

Monitoring the use of gas turbines in industrial power generation is expensive and complex. A University of Aberdeen project aims to use operational data, physical models, and machine learning to save money and simplify the emissions monitoring process.

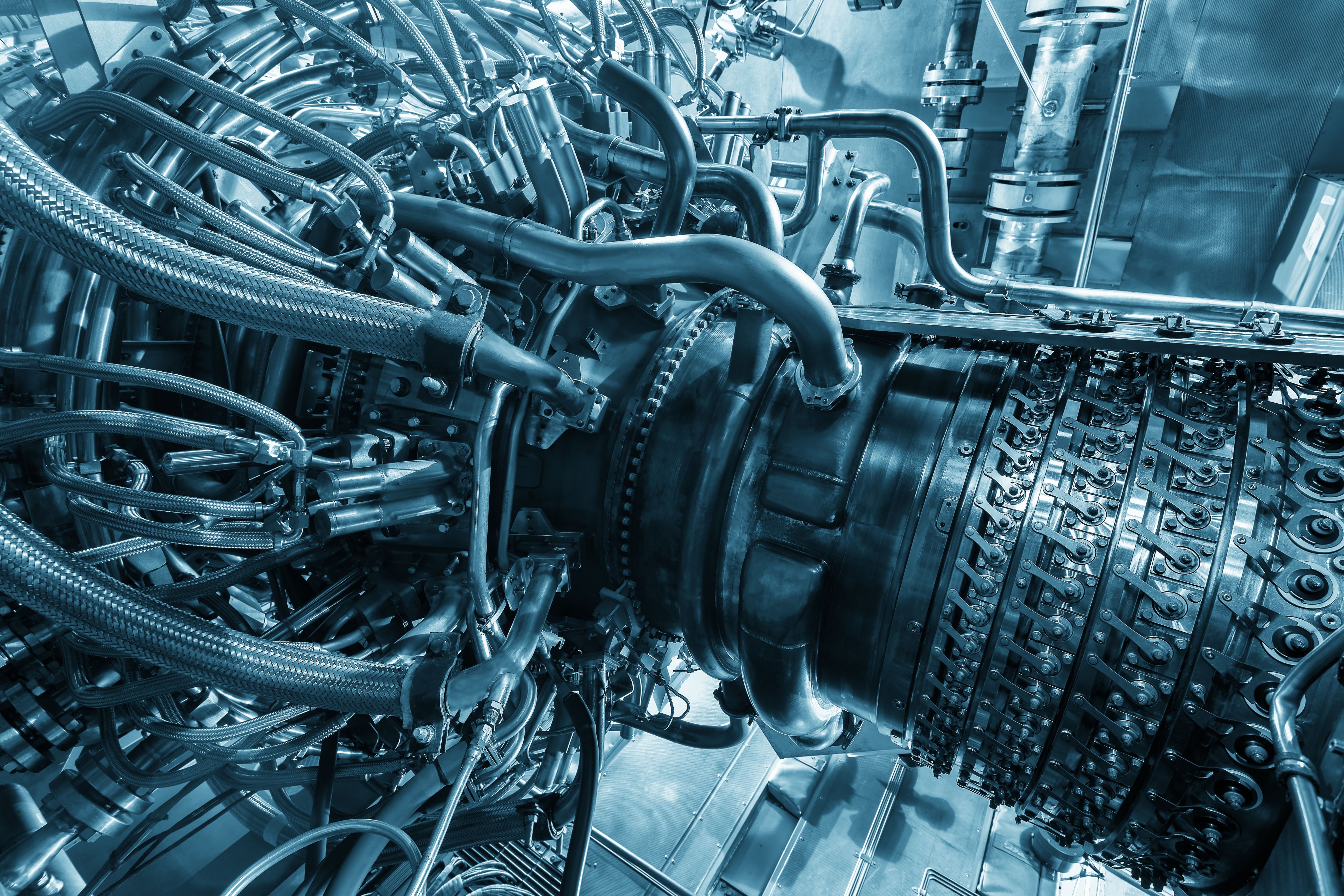

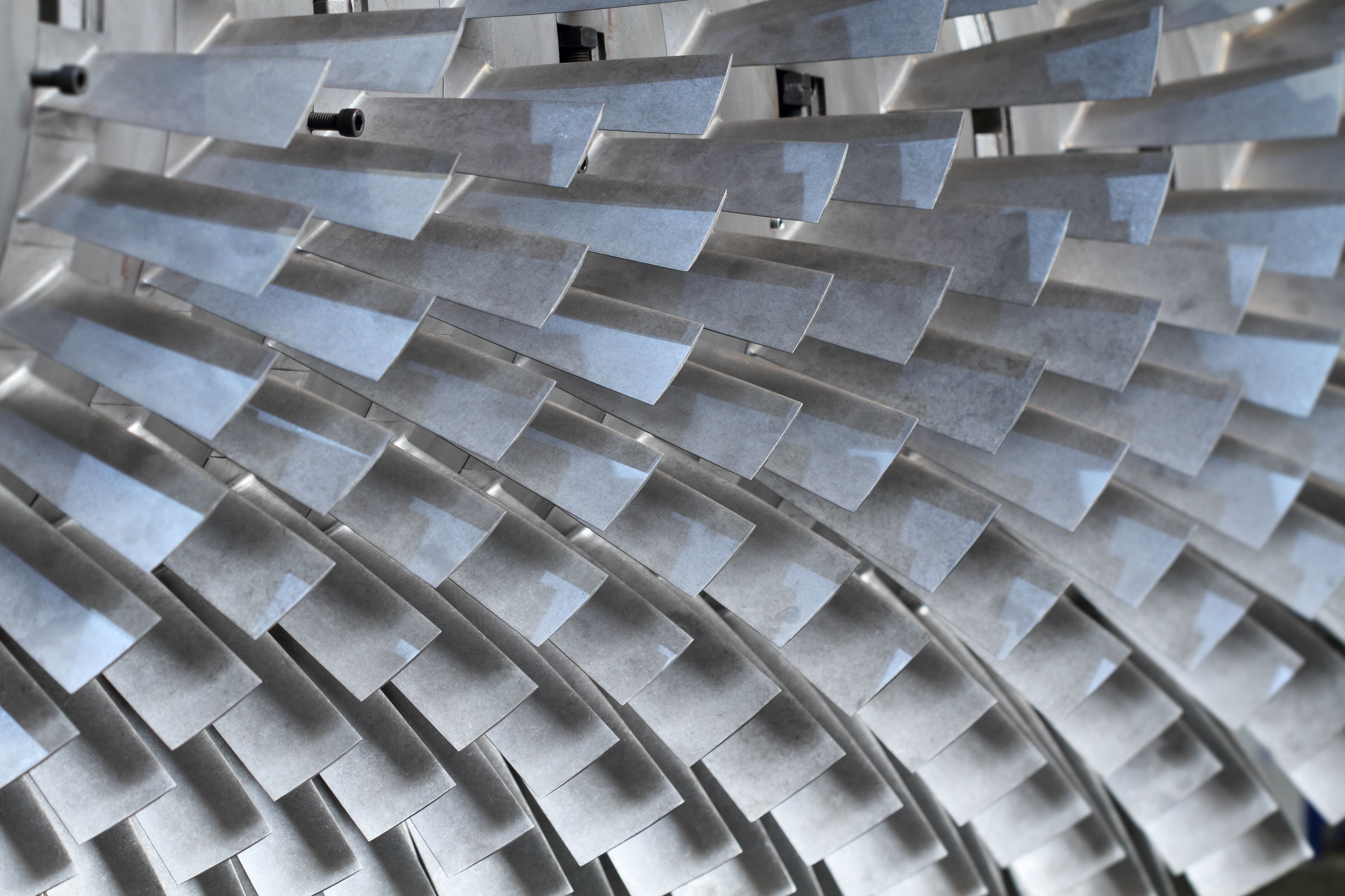

Gas turbines are used throughout the world for the production of electricity and mechanical drive in remote areas. As a result, they are commonly found in the oil and gas industry for the generation of power on rigs. These turbines produce undesirable emissions, primarily carbon monoxide and nitrogen oxides, and therefore require constant monitoring to ensure compliance with current regulations and to minimise their impact on the build-up of global greenhouse gases.

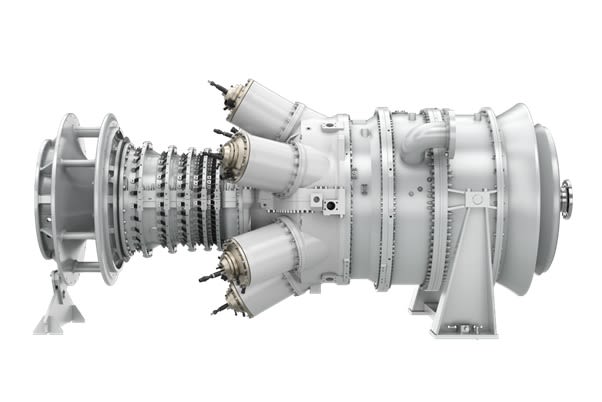

SGT-400 Gas Turbine (source: https://www.siemens-energy.com/global/en/offerings/power-generation/gas-turbines/sgt-400.html)

SGT-400 Gas Turbine (source: https://www.siemens-energy.com/global/en/offerings/power-generation/gas-turbines/sgt-400.html)

Current methods of monitoring emissions are expensive and complex. Gas turbines require daily maintenance in order to ensure accurate readings, and also require an abundance of physical space for the probes and analysing equipment involved in the process. Known as Continuous Emissions Monitoring System (or CEMS), it is a costly system to maintain.

However, advances in data modelling and machine learning are offering hope for an accurate software-based Predictive Emissions Monitoring System (PEMS) which could save both money and space.

University of Aberdeen PhD student Rebecca Potts and academic supervisor and Principal Investigator Dr Georgios Leontidis, the University's Interdisciplinary Director of Data and AI, have partnered with Europe’s largest industrial manufacturing company Siemens Energy to develop this technology with a view to helping them develop a PEMS system over the next four years.

Rebecca said “I come from a mechanical engineering background from my undergraduate degree with an emphasis on machine learning in my final year. As such, I’m quite well placed to be in-between the mechanical side of the gas turbines and the software side of machine learning within the computer science department at Aberdeen. This should help me make more informed decisions about how to go about the project and understand the background and the data that I’m working with.”

Rebecca is currently approaching the end of the first of four years on the project and explains how the first step has been to work towards a functional proof of concept.

“In terms of what we’re working with, we are leveraging operational and emissions data from several gas turbine models, especially those that are very well instrumented. We’re developing deep learning models and leveraging approaches, such as self-supervised learning, to develop algorithms and data-driven models that can predict emissions accurately enough to be competitive against CEMS. Our plan also includes extending our methods to various gas turbine models.”

Rebecca Potts

Rebecca Potts

Rebecca Potts

Rebecca Potts

Georgios said: “We are delighted to have embarked on this project, working together with great collaborators from the global leader in this domain, Siemens Energy Industrial Turbomachinery. Our project aims at developing algorithms that can predict gas turbine emissions more accurately than current approaches. In the absence of CEMS, PEMS can be a cost-effective solution that can support the gas turbine emissions monitoring process of any organisation using gas turbines.”

Tony Latimer, Head of Digital Intelligence (IGT) with Siemens Energy Industrial Turbomachinery Ltd., said: “This is an excellent opportunity for us to develop our emissions monitoring capabilities in conjunction with the experienced academics at Aberdeen. We are motivated to drive down emissions and to demonstrate that we are serious about the environment, and being able to monitor our emissions through intelligent algorithms and machine learning will enable us to offer a viable cost-effective solution to our customers.”